State Grid Solutions:

Background Introduction

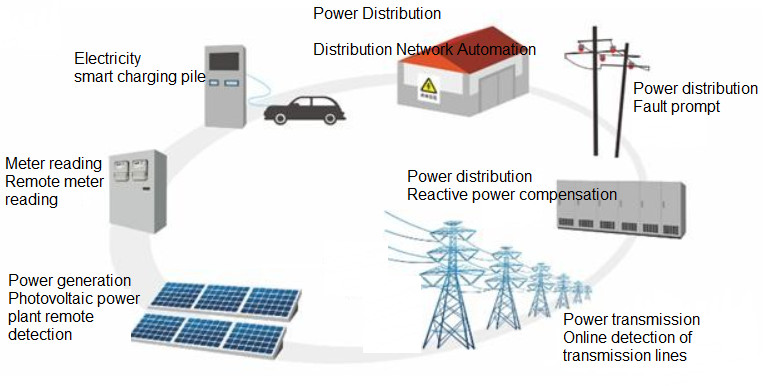

According to the increasing demand in modern electric power through the application of various working scenarios to realize efficient work, real-time interaction of information, and make management and operation more convenient. Feigete State Grid solutions bring intelligent transformation to the electric power industry.

Solution Overview

Feigete State Grid's overall solution, through the application of various work scenarios, achieves efficient work, real-time information interaction, and makes management and operation more convenient.

Combining barcode, RFID, GPS and other technologies to identify inspection point information, record feedback site conditions, enable efficient interaction between management and execution, reduce failure rate, and improve work efficiency.

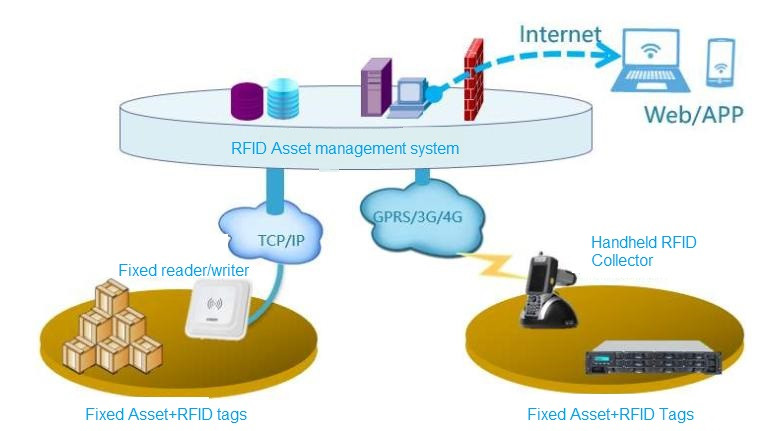

Through RFID management of assets, the management and control of asset service life and personnel are greatly improved, thereby reducing asset management costs.

Line Inspection

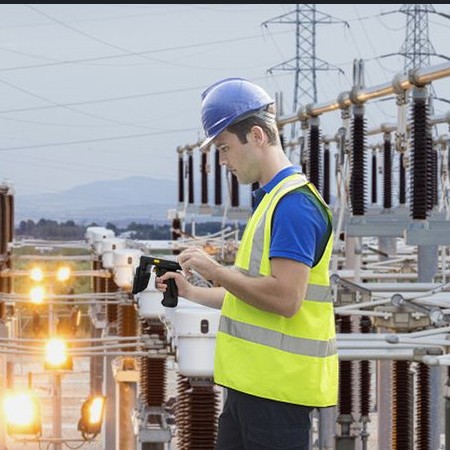

Inspection work is an important measure to ensure the smooth operation of the line, and it is time-sensitive, requiring inspection personnel to inspect every point periodically. The application of RFID makes the inspection work more efficient. The inspection points are installed with RFID tags that record the basic information of the inspection points, and the staff read the tag content in real time through the PDA. And the detection information is transmitted to the management office through the network, and the inspection information is processed in time to improve the inspection efficiency and gain insight into the inspection situation.

Power Distribution Inspection

In the process of power transmission, power distribution is also crucial. The distribution station installs RFID tags for site information, and inspectors need to read the tags and check the operation of the equipment in the site. The site inspection information is wirelessly transmitted to the management office through the handheld, and the inspection information is processed in a timely manner to avoid equipment failures causing site operation.

Smart Grid

In the application of RFID in the power grid, PDA is used in combination with RFID tags. Because of its large reading distance, compared with traditional workflows, it greatly improves work efficiency and reduces data errors caused by manual work. At the same time, it can track the work progress in real time with GPS.

Fixed Assets Inventory

PDA regularly intelligently marks various fixed assets in the power sector, and can track and monitor fixed assets (to be repaired, scrapped, decommissioned, etc.) anytime and anywhere to facilitate asset management and inventory and reduce capital waste.

Advantages:

1) Compared with traditional working methods, it greatly improves work efficiency and data accuracy.

2) Through the collocation of RFID and the site, personnel work management can be realized and inspection efficiency can be improved.

3) Regular inspections are carried out to effectively implement equipment to ensure equipment safety and reduce failure rates.

4) Effective management of assets facilitates rational use of resources and reduces losses.